In May this year, a unique tower crane for the Czech Republic was assembled in Prague 3, Žižkov, with the type of designation Liebherr LH 250 EC-B 12 Litronic. Based on the customer's request, the demolition company TREPART s.r.o., it was delivered to the place of deployment - to the premises of the former Central Telecommunication Building - including qualified operators by KRANIMEX spol. s r.o., a company dealing with the sale, rental and service of Liebherr tower cranes.

Type of crane without tower head (so-called "Flat Top"), into which the Liebherr LH 250 EC-B 12 Litronic is classified as, was delivered to Kranimex rental company specifically for this contract in Žižkov. The crane helps in demolition and rehabilitation work at the site and will be deployed here at least until March next year. The crane is unique for several reasons.

Basic features of the crane

The first specificity is the type itself of the machine. It is one of the top models of the EC-B category, which means it lacks the boom rod tip.

A crane without head section is used for this project proved to be the optimal solution for this project right away. For several reasons: it is more cost-effective (erecting a crane with a crane head to the required height would impose a greater demand on mobile cranes), it is not associated with so many constraints (at higher heights, for example, there is a risk of crossing with the operator´s beams) and last but not least it generally has better static conditions. Also interesting is the function Litronic: when lifting loads, it is possible to switch the machine to a special mode, in which a one-time increase its load capacity by 20%. This function can only be used to a limited extent; when activating it will slow down the crane's speed to 30% of the original values, however it is a useful tool when you need handling heavier loads.

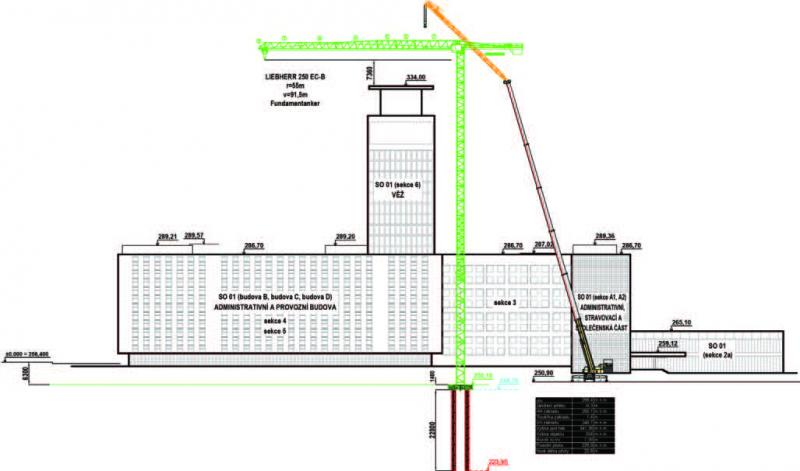

Unique in its height

Liebherr LH 250 EC-B 12 is standard delivered with a hook height of 57.1 metres. In this case, however, the crane had to be erected to a height of 91.5 metres, which is almost double its usual parameters. For such height, the engineers at Kranimex worked together with a structural engineer directly from the Liebherr factory in Biberach. Based on the design requirements, he calculated which parts the crane should be assembled from to meet the reach and load capacity requirements. The optimum crane configuration was then selected. The cranes are then assembled from different parts, called "towers", in this case there are 18 of them. They came from various sources - some of them came from the company's own stock Kranimex, some were borrowed from partner companies. For this method the first foundation tower must be larger and wider (type 500); a special transition tower (from 500 to 256 type) is also needed for the assembly.

Anchoring specifics

An interesting chapter of this realization is the anchoring of the crane at the place of deployment using foundation anchors. This method, together with the method of laying on foundation crosses (portals) with a central concrete weight, is the most common method of anchoring tower cranes. The advantage of foundation anchors is less demanding on the area occupied on the construction site, which is a big plus for many buildings today. Anchors are also the ideal choice when a crane needs to be erected at great heights and cannot be anchored to the building for some reason. At Žižkov, foundation anchors with the type designation 24HC630FA (500HC) were used with a spacing of 2.45 × 2.45 m, corresponding to the dimensions of the first of the five tower parts (type 24HC630TS-0580c).

As this type of foundation generates huge tensile forces (in this case over 10,000 kNm), piles are drilled under the foundation. There are five of them, each 1.2 metres in diameter and going to a depth of 23 metres. The piles are topped by a 7 × 7 × 1.4 m reinforced concrete block with foundation anchors installed. By the way - their location must be very precise, the height tolerance to the project is only 1 mm. When the foundation slab with piles is finished, the work must be properly approved by the structural engineer and the building manager; only then does the actual installation of the crane structure begin.

Assembly a "jigsaw puzzle" for the advanced

The next challenge for the tower crane supplier was its assembly and the logistics itself. The mobile cranes of the well-known company Hanyš - Jeřábnické práce, s.r.o. were called into action. The main assembly machine was an eight-axle "mastodon" LIEBHERR LTM 1500-8.1 with a stated capacity of 500 tons. Other interesting facts from the configuration of this mobile crane include: a base boom with a length of 84 metres, a "wing" anchoring system (Y-shaped), a boom with a length of 49 metres (the so-called "Wippa") and a counterweight with a total weight of 165 tonnes. The main machine was followed by two LIEBHERR LTM 1100-4.2 mobile auxiliary cranes.

Installation of the tower crane took one working week. On the first day, only the main mobile crane was assembled (by an auxiliary mobile crane); meanwhile, a second auxiliary mobile crane assembled the individual components of the tower crane from truck trailers. This was followed by the assembly of the 55-metre jib (done on the ground, then fitted in its entirety to the top of the crane), the successive erection of the tower, the tuning of the top of the crane and, on the last day, the counterweight was fitted to the top of the jib.

Technical parameters of the crane:

| Type designation LIEBHERR | LH 250 EC-B 12 Litronic |

| Version | Stationary |

| Foundation | anchor |

| Height under hook | 91.5 m |

| Jib | 55 m |

| Min. load capacity | 55 m / 3,850 kg |

| Max. load capacity | 2.6–21.5 m / 12,000 kg |

| Electrical power / protection | 76 kW / 125 A |

| Crane trolley jib travel speed | 0–110.0 m/min |

| Arm rotation speed | 0–0.7 U/min |

| Lifting speed | max 96 m/min |

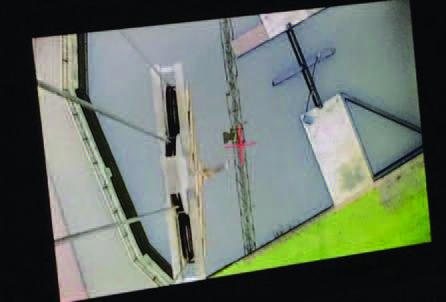

Additional customised equipment

We have summarised the basic features of the Liebherr LH 250 EC-B 12 in the passage above, while more detailed technical data is presented separately in a table off the main axis of the text. However, what is also worthy of attention is the special equipment of the crane, which can be fitted at the customer's request. The analogue camera system monitoring the travel of the crane trolley has proven its worth to Kranimex. This system, which operates on the wireless principle, is powered by energy from mounted solar panels. On the screen in the cab, the crane operator has several useful functions at his disposal, including the ability to enlarge the transmitted image. The system is particularly useful wherever the terrain is rugged, and it would be difficult to rely solely on the instructions of the signalman.

Among the additional equipment fitted to Liebherr cranes, the anti-collision system is worth mentioning. This is a necessary equipment when two or more cranes are on site or, for example, when the crane is working over tracks. The system can automatically ensure that the boom does not move in a predefined restricted zone. However, in Prague Žižkov this system did not have to be activated.

So, if you drive by Žižkov in Prague anytime soon and see the silhouette of this crane on the horizon, you might remember the specifics of this crane and how difficult it was to build it here.

Author: Milan Olexa, Jan Rybář

Photos: Milan Olexa, Kranimex archive and Jaroslav Bzenecký